Volvo is working hard to deliver electric cars to its future cars. But the strategy is changing. Volvo Cars is bringing battery cell technology development and production closer to home and aims to tailor its future batteries to the needs of its customers: a longer range and faster charging times.

It will do so by improving lithium-ion battery technology on its forthcoming second generation of electric cars, starting with the company’s first SUV on a completely new electric-only technology platform.

By the middle of the decade, as it introduces its third generation of electric cars, Volvo Cars plans to improve the range further and integrate the battery pack into the floor of the car, using the cell structure for overall vehicle stiffness and improving efficiency.

In the near term, Volvo Cars plans to work with leading Swedish battery company Northvolt to further increase the energy density of its battery cells by up to 50 per cent compared with what is on the market today. Later this decade, Volvo Cars will also look to break the 1000 Wh/l energy density milestone, in order to achieve 1000km (621 miles) of real driving range.

Current charging times are expected to be cut almost in half by the mid-decade, thanks to better battery technology and continuous improvements to software and fast-charging technology.

As Volvo Cars is moving towards becoming an all-electric car company, the importance of sustainability increases in parallel. While the company will increase the battery energy in its cars over the coming decade, it will also work to continuously reduce their carbon impact.

Battery cells from Volvo Cars’ planned collaboration with Northvolt aim to be produced using 100 per cent renewable energy, while it is working with other battery suppliers to do the same by 2025.

Volvo Cars has a clear strategy to further reduce the carbon impact of batteries by making better use of the valuable materials contained in them. Wherever possible, it intends to remanufacture or reuse batteries, and is also investigating potential second-life applications, such as energy storage.

Where possible, batteries that have reached the end of their lifespan will be recycled by authorised recyclers that are able to offer closed-loop recycling of critical materials for use in future batteries. Volvo Car Group’s planned partnership with Northvolt also raises the possibility of utilising their established recycling operations.

Volvo Cars will also continue to focus on the responsible sourcing of batteries, including through the wider use of blockchain technology. By working more closely with its partners and suppliers, Volvo Cars will strengthen its responsible sourcing even further.

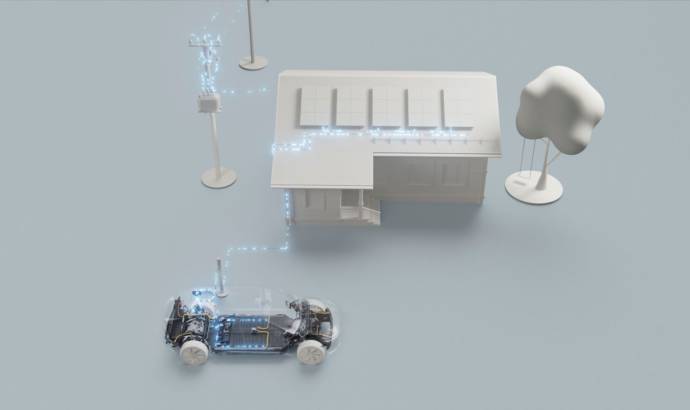

With the successor to the XC90, the company will offer bi-directional charging, allowing customers to offload excess electricity from their car batteries to the power grid. This means electric Volvo drivers can provide energy to the grid when prices and CO2 emissions related to electricity production are at their daily peak, while charging their cars when emissions fall.

Source: Volvo Cars