Rikard Orell, Design Director at Volvo Truck Corp. has envisioned the Volvo Truck of the Future Concept for the year 2020.

Besides featuring a bold exterior design the Volvo Concept Truck 2020 was imagined to work non-stop, controlled by autopilot, in an environment with green

super-motorways that link the continents.

Considering that progress is continuing in an accelerated way, Rikard Orell thinks his vision is not far from the future and the technology for the Volvo Concept Truck 2020 is already available.

Also some areas where the Volvo Concept Truck 2020 is expected to bring improvements are safety, aerodynamic collision protection and drag reduction at the rear.

For more details regarding the Volvo Truck of the Future check out the press release below.

Volvo press release :

Progress is getting ever faster. In just ten years’ time trucks are

going to be a lot different to those of today. At least that is

according to Rikard Orell, Design Director at Volvo Truck Corporation

and one of the brains behind Concept Truck 2020, the Volvo Truck

Corporation’s bold vision for the future.

Long distance haulage for the future: long combinations, controlled

by autopilot, driven non-stop in nose-to-tail convoys on green

super-motorways linking the continents.

This is the vision of the future that generated the ideas behind the

Volvo Concept Truck 2020 design concept. But will it really look like

this in just ten years?

"That is the whole point," says Rikard Orell Design Director at Volvo

Trucks. “Progress is getting ever faster. Because of this our vision

for the future is not that far away. Much of the technology in the Volvo

Concept Truck 2020 is already available; other technology needs to be

developed. One needs to dare to stride firmly into the debate,

demonstrating what one can and will do. Just tinkering at the edges runs

the risk of progress slipping away.”

Safer and more efficient commercial transport

As road transport expands it must also become safer and more

efficient. Volvo’s design concept contains ideas about how that can be

achieved. Some of these ideas can be integrated into production today,

while others are there to arouse interest and start a discussion.

One of the more startling ideas is to link vehicles together

wirelessly into long road-trains that rush across the continents at 90

km/h (56 mph).

"This will be possible when the transport sector’s vision of green

corridors becomes reality," says Rikard Orell. "Here heavy goods

vehicles are separated from other traffic, driving in their own lanes,

rather like a railway, but without the rails."

There are many advantages. Road safety increases, transport services

require less space and wear and tear on the roads decreases. Fuel

consumption and CO2 emissions drop thanks to reduced drag

when a truck is in the slipstream of the vehicle in front. In addition

the driver can rest behind the wheel while the truck effectively drives

itself. If this is counted as idle time, transport times can be cut,

deliveries will be made more quickly and drivers can get back to their

friends and families earlier.

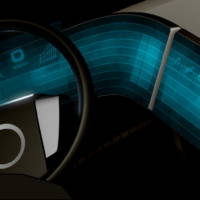

Spacious and airy driver environment

The driver is at the centre of Volvo’s world. It goes without saying

that a design concept from Volvo Trucks contains a great many ideas

about the development of the driver environment. In the Volvo Concept

Truck 2020 the driver’s environment is spacious, airy and free of

disruption.

"We have replaced the traditional dashboard with a thin film panel on

which information is tailored to suit the driver," says Rikard Orell.

“The panel is operated like a touchpad, just like an iPhone. We have

saved a lot of space that way.”

Another space-saving idea is the sleek driver’s seat with its thin,

ventilated mesh backrest, more like a modern office chair than a

traditional driver’s seat. Behind the driver is a futon sofa which folds

out into a wide, comfortable bed in the evening.

The lighting in the cab is divided into zones customised for the

driver’s various in-cab tasks, or for resting. Around the driver are

large areas of glass providing good visibility out of the vehicle and

even into it. This benefits eye contact between the driver and other

road users preventing accidents. Privacy screening and blackout in the

evening are also controlled electronically.

Aerodynamic collision protection

The design team also aimed for a sleek look for the exterior,

reducing the perception of the vehicle’s size. The LED headlamps and

indicators are integrated into the front of the vehicle. The rear-view

mirrors have been replaced by cameras that project their images onto the

inside of the windscreen.

The lower section of the front of the vehicle features integrated

collision protection projecting forwards about half a metre. This ‘nose’

is gentler on oncoming cars in the event of a head-on collision and has

also been shown to improve the aerodynamics of the vehicle.

As Rikard Orell points out, "Because the nose is a safety function,

our starting point has been that it does not count as part of the

maximum permitted vehicle length, just as rear-view mirrors today are

outside the maximum permitted width."

Some things you just do not change. The ‘Globetrotter’ sign on the

roof is still there, but has been redesigned so that it harmonises with

the lines of the vehicle and reduces drag. The driver can also change

the text on the sign from the instrument panel.

The rear end is the next stage

So work on the external design focuses largely on aerodynamics, but

by how much is it really possible to reduce drag on a truck ?

"We have come so far with the front of the vehicle that further

changes to the basic shape provide only marginal improvements," says

Rikard Orell. "However, a lot will happen when we start work on the

design of the rear end of the vehicle. There is a great deal of untapped

aerodynamic potential there."

03 Jun 2010

0