While most manufacturers decided to unveil concepts at this year CES Las Vegas, Nissan came up with something even more clever: a solution for better soundproofing the interior of its cars. The invention can help make car cabins quieter while also boosting energy efficiency.

Nissan will demonstrate the new lightweight sound insulation material, known as acoustic meta-material, this week at CES 2020 in Las Vegas.

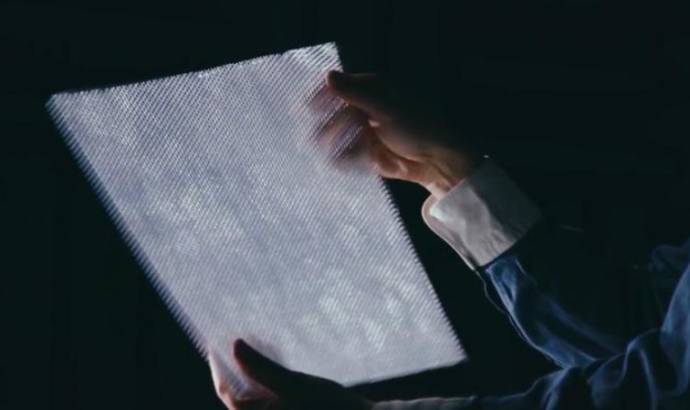

The makeup of the new material is simple. A combination of a lattice structure and plastic film controls air vibrations to limit the transmission of wide frequency band noise (500-1200 hertz), such as road and engine noise.

Currently, most materials used to isolate this frequency band consist mainly of heavy rubber board. Nissan’s new acoustic meta-material weighs one-fourth as much as these while providing the same degree of sound isolation.

Because of its simple structure, the material’s cost competitiveness in terms of mass production is almost the same as, or possibly better than, current materials. Therefore, the material can also be applied to vehicles where the use of sound insulation materials is currently limited due to cost or weight.

Nissan started its research on meta-material technology around 2008. At the time, meta-material was used in high-sensitivity antennas used for electromagnetic wave research. Nissan worked to extend the applicability of meta-material technology to include sound waves, leading to the successful invention of acoustic meta-material.

Making vehicles lighter helps limit the environmental impact of driving by improving energy efficiency. It also enhances enjoyment, as the quiet vehicle cabin makes driving more comfortable.