Nissan released details with their new Dual Injector system, designed for reduced fuel consumption in small-displacement gasoline engines. This unique system that uses an injector for each port instead one per cylinder speeds up the vaporisation process leaving less unburned fuel inside the engine and reducing hydrocarbon emissions.

The Nissan Dual Injector system that uses with 50% less rare metals in the catalyser will also give future vehicles the ability to improve heat efficiency through its continuous valve timing control on the exhaust side.

Nissan’s corporate vice president says that “We consider it important to further improve the fuel efficiency of gasoline engines as demand for gasoline and other internal-combustion systems continues to increase around the world,”

Nissan press release :

Nissan Motor Co., Ltd today announced the development of a Dual Injector system designed to improve fuel efficiency in small-displacement gasoline engines. The new fuel delivery system, the first of its kind in the world*1, uses an injector for each port rather than one per cylinder – speeding up fuel vaporisation, reducing the amount of unburned fuel and reducing hydrocarbon emissions. Nissan will introduce the new system in production vehicles starting early in fiscal 2010.

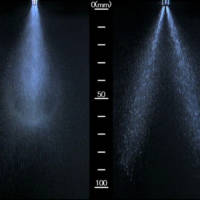

While most current gasoline engines utilise one injector per cylinder (furnishing fuel to two intake ports), the new Nissan Dual Injector system doubles the number of injectors per cylinder. This reduces the diameter of the fuel droplets by about 60%, resulting in smoother, more stable combustion.

The system also adds continuous valve timing control on the exhaust side to conventional intake-side control, improving heat efficiency, reducing pumping losses and raising fuel efficiency by up to 4%*2 in sync with the dual injectors.

While similar in theory to “direct-injection” systems, which also inject fuel directly into cylinders, such direct injection systems are difficult to use on small-displacement engines because they require a high-pressure pump that complicates system design, making component layout less cost-efficient. In contrast, the Nissan Dual Injector system is lighter and structurally simpler because it furnishes fuel at normal pressures, reducing cost by about 60% compared to direct-injection engines of similar displacement.

The new Dual Injector system also uses half the amount of rare metals in the catalyser while maintaining the efficiency of the catalytic conversion system. That number could potentially be reduced to 75% in combination with the ultralow-rare-metal catalysts that were introduced in 2008.

“We consider it important to further improve the fuel efficiency of gasoline engines as demand for gasoline and other internal-combustion systems continues to increase around the world,” said Shuichi Nishimura, Corporate Vice President, Nissan Powertrain Engineering Division. “By widely applying the Dual Injector system on small-displacement engines, we hope to help reduce CO2 emissions and conserve rare metals.”

Nissan has been addressing a wide range of actions under “Blue Citizenship”, which represents the company’s desire to protect the blue planet and to be a corporate citizen that can live symbiotically with people and society. These efforts range from such global issues as the environmental protection to contribution to communities, promoting diversity and making personal mobility available to as many people as possible. Nissan continues promoting the “Nissan Green Program 2010”, based on the “Blue Citizenship” spirit by introducing effective technologies, products and services into the market.

*1: Mass production passenger cars (Nissan’s research).

*2: Compared with Nissan gasoline-powered engines in the same class

14 Jul 2009

0