New details with the Gordon Murray T.25 City Car have been released as the 3-seater electric vehicle will make its first public appearance today in Oxford.

The Gordon Murray T.25 City Car is 2.3 m long, 1.3 m wide and 1.4 m tall, weighting only 575 Kilograms, and powered by a 660cc 3-cylinder engine delivering 51 bhp and 42 lb-ft of torque that are put to the ground via a 5-speed transmission.

The Gordon Murray T.25 City Car is able to hit 62 mph from a standstill in 16.2 seconds, reaches a maximum speed of 90 mph and returns 74 mpg (UK rating) with CO2 emissions of 86 g/Km.

Some of the features on the Gordon Murray T.25 City Car include ABS, traction and stability control, one airbag, and a Formula 1 inspired tubular steel and composite floor chassis.

The Gordon Murray T.25 City Car is expected to enter production in 2012 although information about its price is unknown at this point.

Gordon Murray Design press release :

Monday 28th June 2010, Gordon Murray Design’s T.25 City Car will make its first public appearance at the Smith School’s World Forum on Enterprise and the Environment in Oxford today.

Sir David King, Founding Director of the Smith School of Enterprise and the Environment said:

“Our transport sector is hugely dependent on fossil fuels and we need to de-fossilise our economy as quickly as possible. We know most of the technologies already exist in delivering low carbon transportation and the T.25 and iStream® manufacturing processes are clear examples of how the transition can bring new and exciting developments”.

The T.25 represents a major breakthrough in city car design in the areas of weight, footprint, safety, usability and efficiency. Whilst applying a holistic and fit for purpose approach to the design and development of the T.25, Gordon Murray Design have taken the opportunity to incorporate solutions to a multiple of urban mobility problems into the T.25 design.

A world leading 6 metre turning circle will help with urban manoeuvring and parking whilst its 1.3 metre width opens any opportunity for timed lane zones with 2 vehicles travelling and over taking in one lane. Combining this with the car length, could triple lane usage at peak times. The T.25’s short length also opens an opportunity to park end on to the curb and the door opening allows 3 cars to be parked in one parallel parking space.

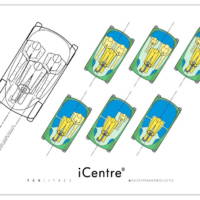

Gordon Murray Design was established in 2007 to develop an innovative and disruptive automotive manufacturing technology trademarked iStream® and the design and prototyping of the T.25 city car was central to both the development and validation of iStream®. This manufacturing process is now industrialised including final factory designs by specialist automotive consultants.

Holger Erker, Managing Director of IPE Engineering said:

“After a complete and comprehensive comparison of the process details and seeing the vehicle prototype build, our conclusion is affirmative that the innovative vehicle and process design of this project is outstanding. From our analysis the iStream®process can be positively qualified as the most promising manufacturing process development in the car industry of the next decade”

The iStream® assembly process is a complete rethink and redesign of the traditional manufacturing process and could potentially be the biggest revolution in high volume manufacture since the Model T. Development of the process began over 15 years ago and it has already won the prestigious 2008 ‘Idea of the Year’ award from Autocar who were given privileged access in order to make their assessment. The simplified assembly process means that the manufacturing plant can be designed to be 20% of the size of a conventional factory.

This reduces capital investment in the assembly plant by at least 80%. Yet the flexibility of this assembly process means that the same factory could be used to manufacture different variants. The iStream® design process is a complete re-think on high volume materials, as well as the manufacturing process and will lead to a significant reduction in full lifecycle CO2.

* Low capital investment / fast return on investment.

* Lightweight.

* Low energy manufacturing.

* Ultra safe structure.

* Flexible product design.

* Long life chassis.

* Low cost variants.

* Recycled materials.

* Reduced distribution costs and damage.

* Low cost accident repair.

* Flexible body in white tooling.

* Small footprint production plant.

* De-centralised manufacturing and assembly opportunities.

* Quiet and clean plants.

* No paint plant at BIW assembly plant.

* Rapid vehicle assembly.

* Low capital investment in tooling.

The T.25 has recently been seen testing on public roads and has featured in many publications but the Smith School World Forum is the first public appearance and Gordon Murray Design are excited to now be able to release the first images of the car’s interior and seating position.

Professor Gordon Murray, CEO & Technical Director of Gordon Murray Design said:

“We are very privileged to have been asked to show T.25 publicly for the first time at the World Forum as the aims of our Company are very much aligned with those of the Smith School and therefore this global event”

28 Jun 2010

0