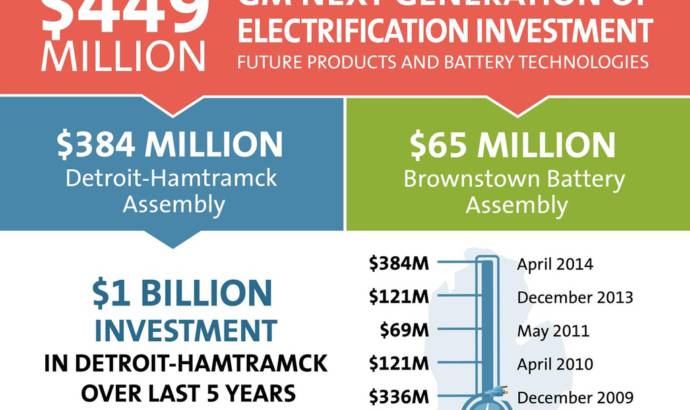

General Motors announced that it will invest $449 million to upgrade manufacturing processes in its preparation for the next generation of electric vehicles and battery technologies.

The investment is the largest to date at both Boston and Detroit factories. It includes $384 million destined for Detroit-Hamtramck in its new Body Shop tooling, equipment, and additional plant upgrades. With this investment, the factory will build the next generation Chevrolet Volt and two future products. This brings GM’s total investment at Detroit-Hamtramck to more than $1 billion over the last five years.

To support the next generation of lithium-ion battery production and future battery systems, GM will invest $65 million in Brownstown Battery Assembly will

The Detroit-Hamtramck Assembly Plant is the world’s only auto factory that mass-produces extended-range electric vehicles: Volt, Cadillac ELR and Opel Ampera: The production is ready to reach markets in 33 countries. In Detroit-Hamtramck, GM also builds the Chevrolet Malibu and Impala sedans.

To help sustain the eco touch of its cars, GM installed here 264,000-square-foot photovoltaic solar panels that can generate up to 516 kilowatts of electricity, or enough to charge 150 electric vehicles per day.

Brownstown Battery Assembly’s 479,000-square-foot, landfill-free facility south of Detroit produces the lithium-ion battery packs for GM’s extended-range electric vehicles.