Built on the same platform as the new SUV GV80, the more and more popular Genesis G80 is one of the most safe cars in its segment due to the materials used to build it.

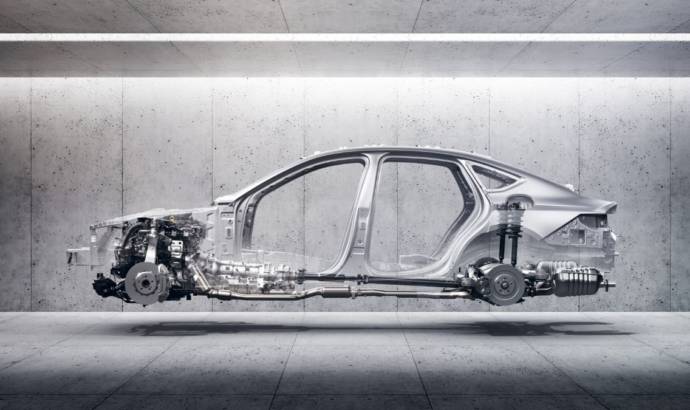

The G80’s rear-drive unibody structure has 6% greater tensile strength than that of the previous G80, thanks in part to increased use of high-strength steel and hot stamped parts ( 42% more hot stamped parts than previous.) They make up the A- and B-pillars, floor crossmembers as well as rocker panels and provide the highest possible strength through hot forming and quenching processes.

The roof crossmembers, transmission tunnel, front chassis extensions and parts of the rear structure are made of advanced high-strength steel, while the cowl, floor panels and rear parcel shelf are comprised of high-strength steel. As a result of this material placement and optimization strategy, the G80’s M3 platform is 6% lighter than that of the previous G80 (55 lbs less).

A newly added horizontal strut brace, die-cast aluminum front and rear shock towers, and a rear subframe benefiting from rear stays and increased bushing size, further enhance rigidity and improve NVH characteristics. Organic geometry was used during the design iteration process to leverage the efficiencies of nature and obtain the lightest and strongest possible structure.

As a result of the careful design and material choices, torsional rigidity of the new model surpasses the outgoing car by 3%.